| |

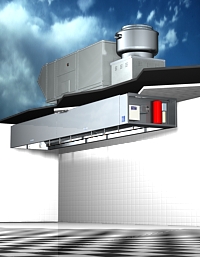

| An effective commercial kitchen

ventilation (CKV) system requires balance air balance

that is. And as the designer, installer or operator

of the kitchen ventilation system, you may be the

first person called upon to perform your own “balancing

act” when the exhaust hood doesn’t work.

Unlike a cooking appliance, which can be isolated

for troubleshooting, the exhaust hood (a non-functioning

sheet metal box by itself) is only one component of

the ventilation system. To further complicate things,

the CKV system is a subsystem of the overall building

heating, ventilating and air-conditioning (HVAC) system.

Fortunately, there is no “magic” to

the relationship between an exhaust hood and its requirement

for replacement or makeup air (MUA). The physics are

simple: air that exits the building (through exhaust

hoods and fans) must be replaced with outside air

that enters the building (intentionally or otherwise).

The essence of air balance: “air

in” = “air out!”

Background If the replacement air doesn’t

come in, that means it doesn’t go out

the exhaust hood and problems begin. Not only

will the building pressure become too “negative,”

the hood may not capture and contain (C&C)

cooking effluents due to reduced exhaust flow.

We have all experienced the “can’t-open-the-door”

syndrome because the exhaust fan is sucking

too hard on the inside of the restaurant. |

|

The mechanical design may call for 8000 cubic feet

per minute (cfm) of air to be exhausted through the

hood. But if only 6000 cfm of outdoor air is able

to squeeze in through closed dampers on rooftop units

and undesirable pathways in the building envelope,

then only 6000 cfm is available to be exhausted through

the hood. The exhaust fan creates more suction (negative

pressure) in an unsuccessful attempt to pull more

air through the hood. There is no piece of equipment

that generates more controversy within the food service

equipment supply and design community than the exhaust

hood in all its styles and makeup air combinations.

The idea that by not installing a dedicated |

|

|

| makeup air supply, the operator

is going to save money (in both first cost and operating

cost) is short sighted. It may be okay if, by design,

all of the makeup air can be provided through the

rooftop HVAC units (this strategy has been adopted

successfully by several leading quick-service chains).

However, in full-service and institutional kitchens

with larger exhaust requirements, it may not be practical

to supply 100% of the replacement (makeup) air through

the building HVAC system.

The solution is to specify an independent makeup

air (MUA) supply. But, once MUA has been added to

the system, the challenge becomes introducing this

air into the kitchen without disrupting the ability

of the hood to capture and/or without causing discomfort

for the kitchen staff. Kitchens are not large and

dumping 7000 cfm of MUA, for example, in front of

a cook line does not go as smoothly in practice as

it does on the air balance schedule! This design guide

presents strategies that can minimize the impact that

the makeup air introduction will have on hood performance,

kitchen environment, and energy consumption.

An exhaust fan in the ceiling could easily remove

the heat produced by cooking equipment. But mix in

smoke, volatile organic compounds, grease particles

and vapor from cooking, a means to capture and contain

the effluent is needed to avoid health and fire hazards.

While an exhaust hood serves that purpose, the key

question is always: what is the appropriate exhaust

rate? The answer always depends on the type (and use)

of the cooking equipment under the hood, the style

and geometry of the hood itself, and how the makeup

air (conditioned or otherwise) is introduced into

the kitchen. Cooking appliances are categorized as

light-, medium-, heavy-, and extra heavy-duty, depending

on the strength of the thermal plume and the quantity

of grease and smoke produced. The strength of the

thermal plume is a major factor in determining the

exhaust rate. By their nature, these thermal plumes

are very turbulent and different cooking processes

have different “surge” characteristics.

For example, the plume from hamburger cooking is strongest

when flipping the burgers. Ovens and pressure fryers

may have very little plume until they are opened to

remove food product. Open flame, non-thermostatically

controlled appliances, such as charbroilers and open

top ranges, exhibit strong steady plumes. Thermostatically

controlled appliances, such as griddles and fryers

have weaker plumes that fluctuate in sequence with

thermostat cycling (particularly gas-fired equipment).

As the plume rises by natural convection, it is captured

by the hood and removed by the suction |

.  |

| This replacement air, which originates

as outside air, is referred to as makeup air (MUA).

The design exhaust rate also depends on the hood style.

Wall-mounted canopy hoods, island (single or double)

canopy hoods, and proximity (back shelf, pass-over,

or eyebrow) hoods all have different capture areas and

are mounted at different heights relative to the cooking

equipment . Generally, a single- island canopy hood

requires more exhaust than a wall-mounted hood, and

a wall-mounted hood requires more exhaust than a proximity

hood. The performance of a double-island canopy tends

to emulate the performance of two back-to-back wall-canopy

hoods, although the lack of a physical barrier between

the two hood sections makes the configuration more susceptible

to cross drafts. Lastly, the layout of the HVAC and

makeup air distribution points can affect hood performance.

These can be sources that disrupt thermal plumes and

hinder capture and containment. Location of delivery

doors, service doors, and drivethrough windows can also

be sources of cross drafts. Safety factors are typically

applied to the design exhaust rate to compensate for

the effect that undesired air movement within the kitchen

has on hood performance. |

|