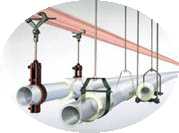

| Pipe Support Systems |

|

| |

|

Pipe Supports and Restraints

• Supports

– Absorb system weight

– Reduce:

+ longitudinal pipe stress

+pipe sag

+ end point reaction loads

• Restraints

–

Control or direct thermal movement due to:

+ thermal expansion

+ imposed loads |

|

| |

|

Support and Restraint

Selection Factors

• Weight load

• Available

attachment clearance

• Availability of structural

steel

• Direction of loads and/or movement

• Design temperature

• Vertical thermal movement

at supports |

|

| |

Rigid Supports

Shoe Saddle Base Adjustable

Support

Dummy Support Trunnion |

|

| Flexible Supports |

|

| |

|

Load and Deflection

Scale

Typical Variable-Load

Spring Support

Small Change in

Effective Lever Arm

Large Change in

Effective Lever Arm

Relatively

Constant

Load

Typical Constant-Load

Spring Support Mechanism |

|

| |

|

Restraints

• Control, limit, redirect thermal movement

– Reduce thermal stress

– Reduce loads on equipment connections

• Absorb imposed loads

–Wind

– Earthquake

– Slug flow

– Water hammer

– Flow induced-vibration

• Restraint Selection

– Direction of pipe movement

– Location of restraint point

– Magnitude of load |

|

| |

|

Anchors and Guides

•Anchor

– Full

fixation

– Permits very limited (if any) translation

or

rotation

•Guide

– Permits movement along

pipe axis

– Prevents lateral movement

–

May permit pipe rotation |

|

| |

|

Piping Flexibility

• Inadequate flexibility

– Leaky flanges

– Fatigue failure

–

Excessive maintenance

– Operations problems

– Damaged equipment

• System must accommodate

thermal

movement |

|

| |

|

| Allowable Pipe Span

Chart |

|

| |

|