|

Building (Automation) Managament Systems

,BMS or BAS

Building Automation Systems (BAS) use computer-based monitoring

to coordinate, organize and optimize building control sub-systems

such as security, fire/life safety, elevators, etc. Common applications

include equipment scheduling (turning equipment off and on as

required)

optimum start/stop (turning heating and cooling equipment on in

advance to ensure the building is at the required temperature

during occupancy)

operator adjustment (accessing operator set-points that tune system

to changing conditions)

monitoring (logging of temperature, energy use, equipment start

times, operator logon, etc)

alarm reporting (notifying the operator of failed equipment, out

of limit temperature/pressure conditions or need for maintenance

Tremendous advances in computer technology are reflected in the

sophistication and falling costs of Direct Digital Control (DDC)

systems for buildings. DDC systems are now affordable for all

but the smallest and simplest of buildings, and allow much finer

control and energy savings than pneumatic controls. Besides flexible

control of lighting and HVAC systems, DDC can also integrate fire

and intruder alarms, security and access systems and local and

wide area computer networks.

Even in retrofit situations with existing pneumatic controls,

it is usually worth examining the use of zone or central digital

controllers. Continued use of pneumatic actuators and sensors

is sometimes cost-effective, but requires periodic compressor

maintenance and more ongoing attention to calibration and adjustment.

Central DDC systems are typically too expensive for buildings

with 10 or fewer HVAC or lighting zones, unless they collect renewable

energy using photovoltaic arrays. However, even in these smaller

buildings, digital controls and equipment should be specified

that: Cost:

Computerized DDC control has evolved rapidly in the last few years

with costs dropping significantly. It is difficult to determine

the "per point" cost of BAS because bundled points included

with HVAC equipment are inherited when common network connections

are made.

A range of C$50 to $300 per point is common, depending on the

mix of included points. This estimated range includes real or

physical points only and does not include the large number of

virtual points included in most systems. These estimates include

remote communication to a networked personal computer and operating

software.

Computerized control is usually the lowest cost option and will

be provided as an integral part of all sub-systems.

The cost to manage and integrate, or have the future potential

to integrate, is extremely low, or in most cases no cost, if included

in the original design request

offer optimal start and stop controls for HVAC plant equipment.

provide occupant-accessible local overrides for temporary off-schedule

use.

have BACNet-compatible sensors, actuators and controllers.

Often DDC zone controllers are suitable and economic for small

applications with fewer than 16 inputs and outputs.

|

ISO 16484-3:2005 specifies the requirements

for the overall functionality and engineering services to

achieve building automation and control systems. It defines

terms, which shall be used for specifications and it gives

guidelines for the functional documentation of project/application

specific systems. It provides a sample template for documentation

of plant/application specific functions, called BACS points

list. The informative function block examples explain a method

to display the referenced functions in system documentation;

they do not standardize the method for programming functions

and applications. ISO 16484-3:2005 covers requirements and

definitions regarding BACS and application software, generic

functions for plant/project specific applications and engineering

functions for building controls and operations. It provides

communication functions for the integration of other dedicated

special system processes. ISO 16484-3:2005 defines a method

for specifying the procurement specifications containing all

essential elements required for the operational functioning

of a BACS. The successful installation and operation of a

BACS requires that its procurement be based on a complete

and accurate functional specification. |

|

|

For larger and more complex buildings, central controllers or

centrally supervised zone controllers connected with a network

offer the most flexibility and potential for energy savings. These

systems should:

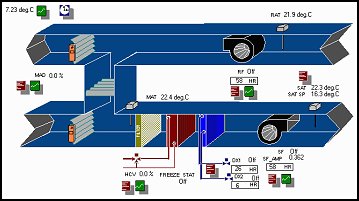

provide a graphic interface for building operators that shows:

floor plans of all areas of the building, locating all controlled

equipment.

schematic drawings of each controlled device, with on/off status,

current sensor readings, setpoints, operator positions, control

constants, and a link that shows the operating control program

code.

graphic trend logs of inputs, outputs and control points selected

by the operator.

graphs and tables of building energy and demand history for all

fuel types.

have BACNet-compatible sensors, actuators, controllers and communications.

use optimal start and temperature-predictor programs for cooling

and heating plant equipment.

offer provide storage for at least 12 months of hourly trend-logging

of flows, temperatures, pressures and other important data for

all plant equipment.

secure dial-up modem access for remote monitoring, supervision

and trouble-shooting by building service companies contracted

by the owner

A good sample specification and protocol for control point names

and equipment control algorithms can be found at the British Columbia

Buildings Corporation website (see Further Information).

DDC systems capabilities should be considered when designing

mechanical and electrical systems. Often, savings can result from

using control software to supplement equipment limitations. For

example, the traditional rule-of-thumb has been to select control

valves with linear process output / control input relationships.

Intelligent DDC programming can automatically compensate for non-linear

valves, reducing costs. Similarly, programs that use the fast

dynamic response of DDC systems can optimally control pump and

fan flows, so pressure drops are lower under non-peak loads. This

saves energy, and can often reduce the number and size of motors,

especially when variable-speed motor controllers are used.

Where natural ventilation and cooling strategies are supplemented

by mechanical systems, their control must be carefully thought

through. Sensors for windows and air inlets and outlets should

signal their opening by occupants, and lockout or reduce mechanically

supplied cooling and ventilation. Automatic systems intended to

close windows and air openings must ensure that occupants are

not endangered.

Good design documentation for each controlled device should include

schematic drawings, listings of control points, expected operating

readings and acceptable range, and sequences of operation. Field

review and commissioning should check to ensure compliance with

documented design intentions, and any changes made should be recorded

for future reference by building operators.

Cautions

Good communications and documentation are essential to a trouble-free

control system.

Sensors, actuators and controllers must be carefully commissioned.

Building operators must be trained in control system use.

Building Managament Systems

Online Demo's

Building Managament

Systems Example Point list

Building Managament

SystemsTypical Ahu Control Screen

|