|

Benefits of Commercial and Industrial Insulation

Conserves Energy by Reducing Heat Loss or Gain

Properly designed and installed insulation systems immediately

reduce the need for energy, a costly ingredient of every product

made.

Controls Surface Temperatures for Personnel Protection and Comfort

Insulation reduces the surface temperature of piping or equipment

to a safer level, resulting in increased worker safety and the

avoidance of worker downtime due to injury.

Facilitates Process Temperature Control

By reducing heat loss or gain, insulation can help maintain the

process temperature to a pre-determined value. Insulation thickness

must be sufficient to limit the heat loss in a dynamic system

or limit the temperature drop, with time, in a static system.

Prevents Condensation on Cold Surfaces

Specifying sufficient insulation thickness with a good vapor retarder

is the most effective means of controlling condensation and limiting

corrosion on cold piping, ducts, chillers and roof drains. Sufficient

thickness is needed to keep the surface temperature above the

dewpoint temperature of the ambient air.

Prevents or Reduces Damage to Equipment From Exposure to Fire

or Corrosive Atmospheres

When used in combination with other materials, fiber glass and

rock and slag wool insulation help provide fire protection in

firestop systems; grease- and air-duct fireproofing; and electrical

and communications conduit and cable protection.

Controls Noise

Special or standard insulation materials can be used to encase

or enclose a noise generating source, forming a sound barrier

between the source and the surrounding area. Insulation installed

in walls and ceilings can provide a barrier to the entry of sound

from the outside or other rooms. Click here for literature on

noise control.

Frost Protection Systems

Heat tracing can be used to protect exposed pipework from freezing.

The most common usage is to ensure prevention of freezing of pipework

for water services. However the term frost protection more widely

referes to maintain pipe contents at temperatures to stoped the

contents solidifying.

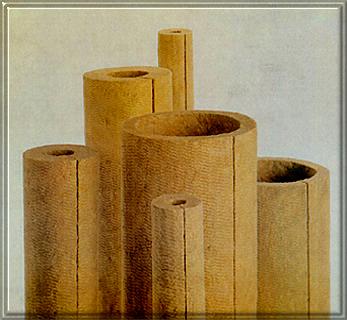

| Fiber Glass Pipe Insulation

Fiber glass pipe insulation is a molded, heavy density,

one piece insulation made from inorganic glass fibers bonded

with a thermosetting resin. It is produced in 3’ lengths

with or without a jacket. It is used on mechanical and process

piping in power, process and industrial applications, and

in commercial and institutional buildings. Most fiber glass

pipe insulations can be used on systems from 0º to

1000º F. |

|

| |

Rock Wool Pipe Insulation

Rock wool (or mineral wool) pipe insulations are precision

cut pipe coverings composed of high density mineral wool.

It can be used in a wide range of applications for hot and

cold piping ranging from –120ºF to 1200º F.

This product is frequently used in high temperature industrial

process power plants, power stations, petrochemical complexes,

etc for steam and process pipe work – and for commercial

hot/cold water systems. It is produced in two half cylinders

and can be supplied either plain or with a FSK type facings.

It comes in 3’ lengths in pipe sizes from 1/2"

IPS to 20" IPS. |

|

| |

|

Elastomeric Pipe Insulation

HFoamed resins combined with elastomers produce a flexible

cellular material. Available in pre-formed shapes and sheets,

elastomeric insulations possess good cutting characteristics

and low water and vapor permeability. The upper temperature

limit is 104.4ºC (220ºF). Elastomeric insulation

is cost efficient for low temperature applications with

no jacketing necessary. Resiliency is high. Consideration

should be made for fire retardancy of the material.

.The easiest and quickest method to insulate already existing

pipework is to use elastomeric (nitrile rubber) insulation

material. This highly flexible non-fibrous insulation material

makes safe application easy, especially in areas of limited

available working space.

Elastomeric insulation’s biggest asset is its excellent

thermal efficiency

|

|

|

|

Foamed Plastic

Insulation produced from foaming plastic resins create predominately

closed-cellular rigid materials. "K" values decline

after initial use as the gas trapped within the cellular structure

is eventually replaced by air. Check manufacturers' data.

Foamed plastics are light weight with excellent moisture resistance

and cutting characteristics. The chemical content varies with

each manufacturer. Available in pre-formed shapes and boards,

foamed plastics are generally used in the low and lower intermediate

service temperature range -182.8ºC to 148.9ºC (-297ºF

to 300ºF). Consideration should be made for fire retardancy

of the material.

|

|

The temperature range within which the term

"thermal insulation" will apply, is from -73.3ºC

(-100ºF) to 815.6ºC (1500ºF). All applications

below -73.3ºC (-100ºF) are termed "cryogenic,"

and those above 815.6ºC (1500ºF) are termed "refractory."

Thermal insulation is further divided into three general

application temperature ranges as follows:

A. Low Temperature Thermal Insulation

1. 15.6ºC through 0ºC (60ºF through 32ºF)

-- i.e. Cold or chilled water.

2. -0.6ºC through -39.4ºC (31ºF through -39ºF)

-- i.e. Refrigeration or glycol.

3. -40.0ºC through -73.3ºC (-40ºF through

-100ºF) -- i. e. Refrigeration or brine.

4. -73.9ºC through -267.8ºC (-101ºF through

-450ºF) -- i. e. cryogenic.

B. Intermediate Temperature Thermal Insulation

1. 16.1ºC through 99.4ºC (61ºF through 211ºF)

-- i.e. Hot water and steam condensate.

2. 100.0ºC through 315.6ºC (212ºF through

600ºF) -- i.e. Steam, high temperature hot water.

C. High Temperature Thermal Insulation

1. 316.1ºC through 815.6ºC (601ºF through

1500ºF) -- i.e. Turbines, breechings, stacks, exhausts,

incinerators, boilers. |

| |

|

| Pipe Insulation

Schedule |

|

| |

|