|

Cooling Tower

Cooling towers are evaporative coolers used for cooling water

or other working medium to near-ambient temperature. Cooling towers

use evaporation of water to reject heat from the system. They

vary in size from small roof-top units to very large hyperbolic

structures (as in Image 1) that can be over 120 meters tall and

100 meters in length or rectangular structures (as in Image 2)

that can be over 40 meters tall and 80 meters long.Cooling towers

can generally be classifed by use into either industrial or HVAC

(air-conditioning) duty.

Industrial cooling towers can by used to reject heat from various

sources such as machinery or heated process material.

An HVAC cooling tower is a subcategory rejecting heat generated

by a chiller. As heat loads increase, water-cooled chillers are

more energy efficient than air-cooled chillers. Large office buildings,

hospitals, schools typically use a cooling tower as part of their

air conditioning systems.

Generally, industrial cooling towers are much larger than HVAC

towers and are entirely erected on site. HVAC cooling towers can

be compact enough to factory assemble and ship nearly complete.

|

Cooling towers are used in central air conditioning systems.

The function of the cooling tower is to cool the warm water

from the chiller condenser. Following the central air conditioning

system cycle, the heat from the rooms in a building is transferred

to chilled water, which is then transferred into the refrigerant,

and finally to the cooling water. The cooling tower is at

the final point of the heat transfer. The heat is transferred

to the atmosphere.

The heat in the cooling water is removed by letting moving

air come into contact with it. Water is normally spread

out and allowed to drop down by gravity from a height. Plastic

fillings are arranged so as to increase the wetted surface

of the water while it is dropping, while at the same time

provide better contact between the air passages and the

water.

There are basically 2 types of designs:

Cross Flow

Counter Flow

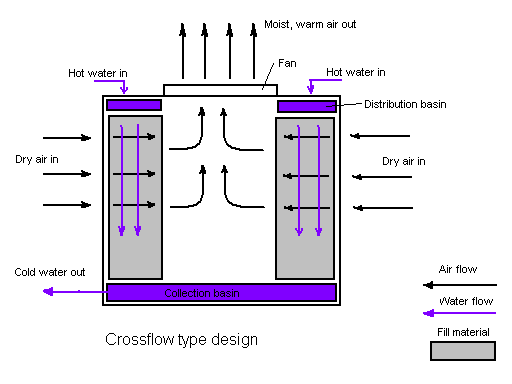

Cross Flow |

|

|

|

|

As the name suggests, the flow of water is at right angles to

the flow of air. The cooling tower for this type of design is

usually shaped like a box. Warm water is pumped to the top of

the cooling tower where it is distributed to the sides and allowed

to drop through small holes. Plastic air intake louvers at the

sides of the cooling tower allow the water to spread out while

dropping. Air from the outside is sucked into the cooling tower

by several fans located at the top. The incoming air comes into

contact with the dropping water, and the latter is cooled. The

cooled water is collected at the bottom of cooling tower. This

water is then pumped out again and circulated through the chiller.

The heat from the chiller is transferred to it again. The warm

water then returns back to the top of the cooling tower and the

cycle starts again.

Counter Flow

Counter flow cooling towers have the air passage flowing directly

against the flow of the water. As with the cross flow design,

water is allowed to spread out with the help of air inlet louvers.

Their bottle like shape characterizes this type of cooling towers.

There is only one single fan at the center. Fitted below the fan

is a rotating water pipe distributor. The pipes of the water distributor

shoots water only from one side. The action of the water pressure

shooting from one side rotates the distributor. The water is thus

dropped evenly over the air inlet louvers. The water dropping

by gravity meets head on with the up moving air current sucked

in by the fan. The air cools the water. The water collected at

the bottom of the cooling tower is pumped to the chiller, becomes

heated up again, and is then returned back to the cooling tower

for cooling.

Water Treatment

In cooling towers, the cooling effect is achieved by evaporation

of a portion of the water passing through it. As the water is

evaporated, impurities remain in the recirculating water. The

concentration of the dissolved solids increases rapidly and can

reach unacceptable levels. In addition, airborne impurities are

often introduced into the water. If the contaminants are not controlled,

they can cause scaling, corrosion, and sludge accumulations which

can reduce heat transfer efficiencies.

In order to control the concentrations, it is necessary to bleed

a small amount of circulating water from the system and top up

with fresh water. If the site conditions are such that constant

bleed-off will not control scale or corrosion, chemical treatment

is necessary. Even with bleed-off or chemical treatment, it is

still necessary to control biological contamination. The growth

of algae, and other microorganisms can reduce system efficiency

and may even contribute to potentially health hazards. Biocides

are used to treat the water to control the biological growths

Cooling Tower Water Management

|