|

Dust Explosions

A dust explosion is very similar to a gas or vapour cloud

explosion, i.e. when a volume of a flammable mixture is ignited,

resulting in a rapid pressure increase and fire moving through

the cloud. A dust explosion occurs when a combustible material

is dispersed in the air forming a flammable cloud and a flame

propagates through it. This of course also depends on the

supply of oxygen to the fire, and the concentration of the

fuel, if either of these are in too high or low then the explosion

will not occur.dust explosions are common and costly in a

wide array of industries such as petrochemical, food, paper

and pharmaceutical. It is imperative that practical and theoretical

knowledge of the origin, development, prevention and mitigation

of dust explosions is imparted to the responsible safety manager.

WHAT IS AN EXPLOSION

In an explosion a large quantity of energy is released

in a short time, causing a fast pressure raise. A bursting

pressure vessel is an example of a physical explosion, because

no chemical reaction takes place. A dust explosion is a

chemical explosion: the suspended dust particles react violently

with the oxygen in the atmosphere, which causes the mixture

to heat up swiftly. In a closed vessel the expanding atmosphere

creates overpressure |

|

|

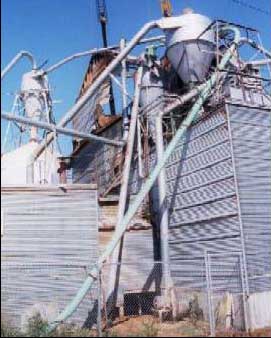

The Prevalence of Dust

Many materials, ranging from baking flour to metal dusts, can

fuel dust explosions when present in a finely divided state. Some

materials are intentionally used in a powder or dust form in manufacturing

while other dusts are created as unintentional byproducts. Examples

of materials that have historically caused dust explosions include:

Cosmetics

Coal

Dyes

Grain and other dry foods

Metal

Pharmaceuticals

Plastic and rubber

Printer toner

Soaps

Textiles

Wood and paper |

|

In the year 2003 alone, there were at least 14 deaths and 81 injuries

related to dust explosions. In response to these and several other

recent dust explosions, the U.S. Chemical Safety and Hazard Investigation

Board (CSB) recommended that government agencies, insurers, and

others provide their inspectors with increased training on recognition

and prevention of dust explosion hazards. This and the publicity

from recent catastrophic dust explosions will likely increase

enforcement of standards for the prevention of dust explosions

by inspectors. When inspectors identify dust explosion hazards

or issue citations to facilities, Exponent assists clients in

quantifying dust explosion hazards and evaluating the validity

of citations issued by government inspectors. We also assist clients

in identifying cost-effective methods for abating dust explosion

hazards.

Addressing the Issue

Exponent designs testing programs to quantify the dust explosion

hazards of materials in client’s facilities using both standard

ASTM testing methods and methods developed by Exponent. Based

on the measured hazard level, when appropriate, we assist the

client in identifying mitigation techniques and applicable standards

and regulations for the prevention of dust explosions including

standards developed by the NFPA. Methods to prevent or mitigate

explosions include:

Preventing releases of fugitive dust into facilities

Housekeeping to remove accumulations of dust

Eliminating ignition sources

Inerting explosive atmospheres

Fire and explosion suppression systems

Segregating areas with dust explosion hazards

Properties that affect the Dust Explosion Hazard

Preventing Dust Explosions

Mitigation Methods

Dust Explosion Cases

|