|

FREEZE PROTECTION DESIGN PROCEDURE

1. TEMPERATURE DIFFERENTIAL

Determine the temperature differential to be

maintained by subtracting the ambient temperature

from the fluid temperature to be maintained. (TF -TA).

Typically, for pipe freeze protection applications, the

pipe temperature should be maintained at 40°F. Pipe

temperatures should be maintained at 110°F for clog

prevention of grease disposal lines and 40°F for viscosity

maintenance of fuel oil lines.

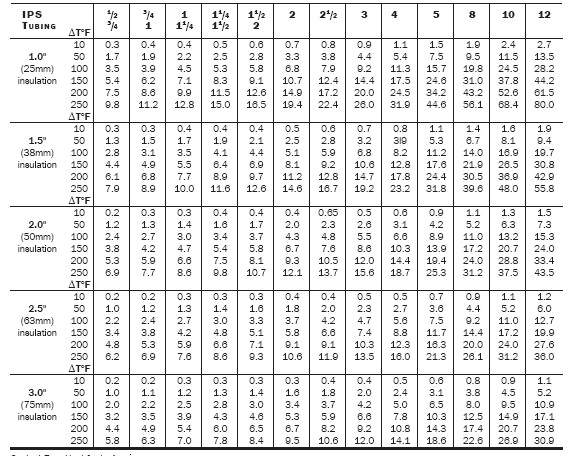

2. HEAT LOSS

Use Table 1 to look up the heat loss associated with

the pipe diameter and thickness of insulation. If a rigid

insulation such as calcium silicate is used, the pipe

heat loss should be increased to that associated with the

next larger size. Insulation should also be oversized when

using any cable other than the standard self-regulating

HSR, without overjacket. This will compensate for the

space of the heating cable. As an example, you would

use 2-inch pipe diameter heat losses for 11/2 inch pipe

heating application if rigid insulation were used. Heat

loss figures from Table 1 include a 10% safety factor.

Another Table

3. ADJUSTMENTS TO HEAT LOSS VALUES

The heat losses in Table 1 are based on glass fiber

insulation. If other insulations are used, multiply the

heat loss value by the correction factor (shown in

Table 2) for your insulation.

Heat losses are based on outdoor applications with 20

mph wind. If piping is used indoors, multiply heat loss

values by 0.9.

4. DETERMINE CABLE P0WER

Using heat loss determined above, select appropriate cable from

Performance and Rating Data chart. For heat loss in excess of

20 W/ft, use multiple cables. For example, for heat loss of 23

W/ft, use two 12 W/ft cables. Cable power may exceed heat loss

by up to 50%. It is also possible to spiral cable on pipe such

that the power applied to the pipe exactly matches the pipe heat

loss. For example, for heat loss of 13 W/ft, a 10 W/ft cable can

be spiraled on the pipe such that 1.3 feet of cable are wound

on every foot of pipe, resulting in exactly 13 W/ft being applied

to the pipe. However, spiraling requires significant extra labor

to install and significant clearance around the pipe.

EXAMPLE

|