| |

|

|

|

| |

| Kitchen ,Canopies and Hoods ,Air Volume Calculation |

| |

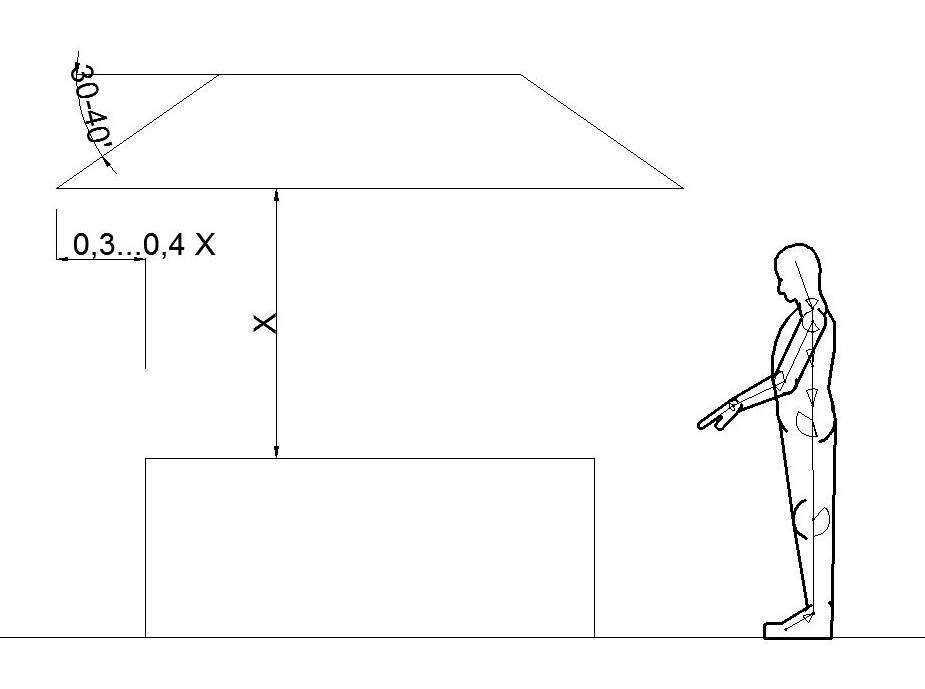

| The removal of fumes and steam from cooking

and industrial processes should be done as near to the source

as possible. Warm fumes and steam rise quickly and spread

over a comparatively large area of the kitchen and must be

'picked up' and removed quickly. To deal with this sort

of local problem by increasing the general ventilation rate

of the room is not always economical or convenient due to

the large volume of air extraction necessary to reduce the

spread of the fumes. In such cases a canopy, or hood, would

be fitted directly above the equipment and overlapping it

by up to 300 mm all round to collect the fumes. The canopies

and fans should be of sufficiently large capacity to 'hold'

and carry away the fumes without undue spillage from the

mouth of the canopy.

To achieve this, the velocity of the air through the open

area between the canopy and the equipment must be sufficiently

high to draw in fumes near the edge of the equipment against

the eddying effects of local draughts which could be caused

by the movement of people around the equipment. |

| |

| Air Volume Where the items of cooking equipment

to be placed under a canopy are known, the total of the

volumes of air required for each piece of equipment will

constitute the extract volume to be provided by the canopy

extract fan/s. (See Table 1 for volume of air required for

cooking equipment). Where the equipment is not known, the

formula shown below can be used. This formula uses the base

area of the canopy, rather than the open perimeter area

used in earlier formulae, and more closely matches the volume

of hot air rising from the cooking equipment. The volumes

obtained by this formula should be regarded as minimums

and no harm will result if they are increased by 50%.

Vol. m³/s = L.metres × W.metres × K, where

K =

0.25 for domestic

0.30 for Light Commercial

0.40 for Commercial and Light Industrial

0.50 for Heavy Commercial and Industrial (Welding, etc.)

(The factor K represents the face velocity (m/s) of the

airflow at the canopy)

Plastic flexible ducting should not be used to extract

from kitchen canopies, as it is very difficult to clear

and would constitute a fire hazard. Steel ductwork should

be used, with adequate access panels for cleaning. In special

cases, flexible metal ducting could be used, but only where

it is short enough to be easily dismantled for cleaning

or replacement. |

| |

| Example A canteen kitchen (equivalent to

a light commercial kitchen) is to have a canopy 3 m x 1.25

m covering cooking equipment not yet specified.

L = 4m

W = 1.25m

K = 0.3

Air req. m³/s = 3 × 1.25 × 0.3 = 1.5 m³/s

(5400m³/h)

Other points to consider:

a) Minimum height from floor to underside of canopy 2m

b) Air replacement based on 75-85% of extracted air

c) Temperature of replacement air must not be below 10oC

when coming into contact with cooked food

d) Maximum duct velocity 6m/se |

|

|

| 1) Give an adequate air flow. Use a minimum

ventilation rate of 25 ACH for commercial kitchens, increasing

these figures as necessary to deal with higher than average

loading and cooking equipment. When calculating the amount

of air necessary to give the selected ACH it is usual to base

the volume of the kitchen on a height of 3m. This will automatically

compensate for different ceiling or roof heights by increasing

the ventilation rate for a low ceiling, and reducing it for

a high ceiling. |

| |

| 2) Specific Volumes for Cooking Equipment. Current

practice for commercial kitchen ventilation extends the guidelines

for sizing ventilation schemes. Whilst retaining the minimum

of 20-30 ACH, specific quantities of air to be provided for

each piece of cooking apparatus are now available. Therefore,

when the details of the equipment are known, a more accurate

assessment of the air volume required can be made. These requirements

can result in substantially higher rates of extraction than

the minimum rates, and will take much of the uncertainty out

of deciding by how much the minimum must be exceeded. The

volumes can be used for determining both general extraction

and canopy extraction requirements. |

| Table

1: Kitchen Cooking Equipment Volume Requirements

|

| Apparatus

|

m³/h

|

m³/s

|

l/s

|

ft³/min

|

| Cookers per m² |

1080 |

0.3 |

300 |

640 |

| Pastry ovens |

1080 |

0.3 |

300 |

640 |

| Fish fryers |

1620 |

0.45 |

450 |

950 |

| Grills |

900-1080 |

0.25-0.3 |

250-300 |

530-640 |

| Steak grills |

1620 |

0.45 |

450 |

950 |

| Salamanders |

1620 |

0.45 |

450 |

950 |

| Boiling pans (140-180 litre) |

1080 |

0.3 |

300 |

640 |

| Steamers |

1080 |

0.3 |

300 |

640 |

| Sink (sterilising) |

900 |

0.25 |

250 |

530 |

| Bain Marie |

720 |

0.2 |

200 |

420 |

| Tea sets

|

540-900

|

0.15-0.25

|

150-250

|

320-530

|

|

Alternatively, calculations can be based on

the number of meals prepared per hour, multiplied by 10-15,

to give an extract volume in litres per second. This method

highlights the different requirements between, for example,

an expensive restaurant with one sitting per table per evening,

to steak bars with around 3-4 sittings/table/evening, to pizza

restaurants (semi fast food) with 5-6 and a burger bar. The

amount of cooking, hence air movement required, increases

the faster the food. |

| 3) Locate extract units as high as possible

and as near the source of the fumes as convenient. Hot moist

fumes from cooking operations rise fast to ceiling level,

and unless they are removed quickly from that level they will

spread over ceiling, walls and windows depositing the moisture

content and grease as it condenses on the cooler surfaces.

Roof lights and lantern lights are sometimes an ideal location

for extract units in a commercial kitchen as they are usually

over some cooking equipment at or near the centre of the kitchen,

and it is a simple matter to fit roof fans in the glazing.

If due to some obstruction it is not possible to site the

unit at high level directly above the cooker, then keep it

at high level and move it a foot or two to one side. This

is better than putting the unit immediately above the cooker

but only half way up the wall, as the velocity of the steam

and fumes would carry them past the unit to ceiling level

where they would spread horizontally and hang about for some

time before cooling sufficiently to drop to the level of the

extract point. This is a common fault in domestic kitchens,

the low siting of the unit sometimes allowing cooking fumes

to float through the top of a doorway before they can sink

low enough to be extracted by the fan. |

| |

| 4) Use canopies over 'heavy' cooking equipment,

particularly in commercial kitchens, to collect and 'hold'

the fumes at source. Estimate the total volume of air required

for the kitchen, subtract the volume required for the canopy,

then allow units over the wash-up and food preparation sinks

to make up the difference. Canopy grease filters are necessary

to remove the bulk of the oil and fat droplets from the air

before it passes along ducting and through extract fans. |

| |

| 5) Ensure ample air replacement openings, well

distributed to eliminate local draughts and to spread the

supply of fresh air. Some air replacement from adjoining rooms

is not a disadvantage as the flow of air through the doorways

will reduce the possibility of fumes from the kitchen passing

through to these adjoining rooms. Extract units should

be switched on as soon as any cooking apparatus is in use

to prevent a build-up of hot fumes, and should be left running

for 20 to 30 minutes after cooking is finished to clear

away any residual fumes and hot air convected from the cooker

surfaces. |

| |

| Structure

of the kitchen |

| Kitchen

,the products |

| Kitchen,Human

resources |

| Kitchen

,Hygiene aspects |

| Kitchen

,Layout |

| Kitchen

,Ventilation |

| |

| |

| Back

to Hvac App. Commercial Kitchen Main Page |

| Back to Hvac

Expert Main Page |

|

|

|

|

|

|

|