|

Fixed-plate exchangers

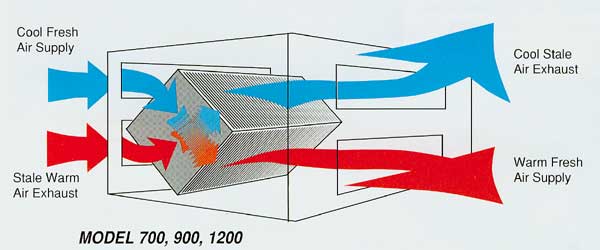

Fixed plate heat exchangers, commonly known as air-to-air

heat exchangers, can reduce laboratory energy consumption.

The transfer of waste energy from exhaust to laboratory

make-up air depends on the location and characteristics

of the air streams. These air streams are separated by plates,

which are usually augmented with fins. The heat exchange

principle is simple: warm exhaust air heats a fixed plate,

which, in turn, heats the cool make-up air on the other

side of the plate. This exchanger uses no transfer media

other than the plate-forming wall of the exchanger

| Why I prefer PLATE over WHEEL

|

| |

| 1-There is a cross leakage

in energy recovery wheels.Cross leakage through the

energy recovery wheels ranges from 2% to 5% between

the supply and exhaust air streams . In many applications

(especially where odors, pathogens or other harmful

pollutants are present), it is clearly unacceptable

for exhaust air (EA) to leak into the outdoor air (OA)

or fresh air stream being furnished to the conditioned

space.I don't want to give air form toilettes to dining

room .Some standart give permission to toillettes air

but I don't !!! |

|

|

| 2-The remedy applicable to wheel systems

is to increase OA airflow thereby pressurizing

this air stream. As long as this pressure gradient is

maintained, the majority of the leakage is from OA to

EA, thus reducing, if not eliminating the exhaust air

transfer. This imbalance can represent a substantial

inefficiency, e.g. 700 CFM of OA may be required to

provide 500 CFM to the conditioned space. It is not

uncommon for “lost air” to account for 25-30%

of a wheel’s rated airflow. |

| |

| 3-Power consumption:A

dedicated motor is required for rotation of the wheel.

For systems installed in cold-weather climates, an effective

defrost mechanism will require yet another draw on available

power. PLATE HEAT EXHANGERS has no moving parts at all. |

| |

| 4-Maintenance is generally

acknowledged as the real Achilles’ heel of wheel

systems. Wheel-type ERV is perhaps the least forgiving

of all HVAC equipment. If not properly serviced, it

will fail – often within a few years of installation.

Routine maintenance generally requires disassembly of

the unit, cleaning/reconditioning of the wheel, re-assembly

and re-calibration of the mechanicals. This is a time-consuming

and costly process requiring the attention of a trained

technician. In addition, during the maintenance process,

no energy recovery takes place, i.e. the heating or

cooling equipment must work to condition raw, outside

air. |

| |

Air

to air plate heat exchanger selection software (from HOVAL)

|